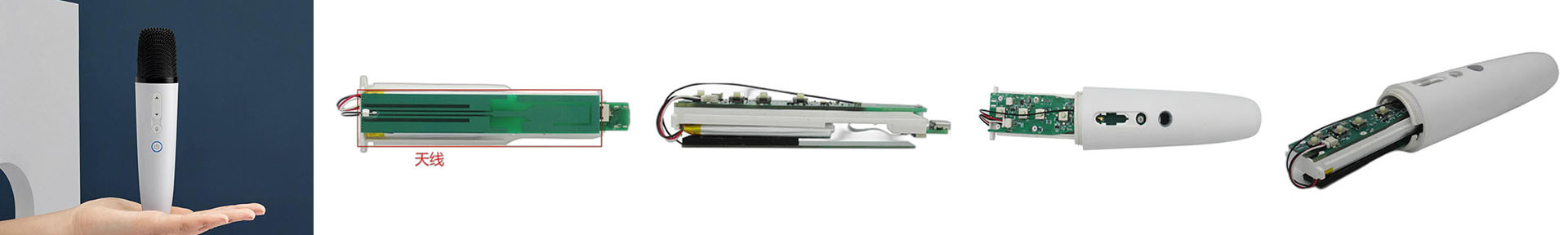

Case study: Cowin-Low frequency hard board PCB antenna power microphone durable stability

Customer Background:

Shanghai Firestone Technology co., Ltd. is a high-tech enterprise focusing on audio and video intelligent product design and research and development. Headquartered in Shanghai, it has cooperated with mainstream first-line brands such as Ali, Baidu, Huawei, Xiaomi, Skyworth, TCL and Jupin, and is a leader in the vertical field.

Business requirements:

Use frequency of 650-700mhz, families and KTV entertainment venues, the use distance within the radius of 10M can not appear broken communication and noise.

Problem Description:

The original antenna scheme is a product design directly on the motherboard, what we call on-board antenna, in use process cannot guarantee business requirements above, the actual test, the original antenna only conform to the signal within the radius of 2 m, after discussions with several communication antenna company, finally choose cowin accept antenna Q1 product research and development work.

The challenge:

Stability and anti-jamming signal is the foundation of the microphone wireless communication solutions, space variety and all kinds of electronic products of complex application environment of close packing, causing serious interference signal, this requires a larger antenna position and greater grounding area to meet the demand of antenna design;The inner space of the microphone (long 100MM, inner diameter 25MM) has been filled with the main board components needed for the function and a large-capacity battery (long 66* wide 20* thick 7MM). The large-capacity battery and narrow space bring great challenges to our engineering team.

Solution:

1. The motherboard of the product is loaded into the motherboard bracket and then pushed into the shell. The antenna and the motherboard or the motherboard bracket must be connected in advance.

2. One side of the mainboard bracket is a function button, so the antenna cannot be installed, so the antenna can only be installed on the other side. The other side is a large-capacity battery, which is the biggest killer affecting the performance of the antenna.

3. After close cooperation and analysis by structural engineers and RF engineers, isolation foam with a thickness of 5MM is added to the ANTENNA PCB board to create a reasonable safe distance between the antenna and the battery and minimize the impact of battery radiation on the antenna.

4. The determination of the antenna position and the space given by the structural engineer determine the antenna size, so we define the antenna size as 100* 17MM in length.

5. The use of engraving machine allows engineers to greatly shorten the development time, after 5 times of rigid sample making, finally successfully developed a long 100* wide 17* thick 1MM double panel antenna, up to 4.8dB gain and 44% efficiency, and double panel antenna grounding becomes larger, perfect improve the antenna anti-interference ability and long-distance transmission superior performance.

Economic benefits:

The customer successfully launched the product, which has sold 500,000 units and is still booming.

Shanghai Firestone Technology co., Ltd. is a high-tech enterprise focusing on audio and video intelligent product design and research and development. Headquartered in Shanghai, it has cooperated with mainstream first-line brands such as Ali, Baidu, Huawei, Xiaomi, Skyworth, TCL and Jupin, and is a leader in the vertical field.

Business requirements:

Use frequency of 650-700mhz, families and KTV entertainment venues, the use distance within the radius of 10M can not appear broken communication and noise.

Problem Description:

The original antenna scheme is a product design directly on the motherboard, what we call on-board antenna, in use process cannot guarantee business requirements above, the actual test, the original antenna only conform to the signal within the radius of 2 m, after discussions with several communication antenna company, finally choose cowin accept antenna Q1 product research and development work.

The challenge:

Stability and anti-jamming signal is the foundation of the microphone wireless communication solutions, space variety and all kinds of electronic products of complex application environment of close packing, causing serious interference signal, this requires a larger antenna position and greater grounding area to meet the demand of antenna design;The inner space of the microphone (long 100MM, inner diameter 25MM) has been filled with the main board components needed for the function and a large-capacity battery (long 66* wide 20* thick 7MM). The large-capacity battery and narrow space bring great challenges to our engineering team.

Solution:

1. The motherboard of the product is loaded into the motherboard bracket and then pushed into the shell. The antenna and the motherboard or the motherboard bracket must be connected in advance.

2. One side of the mainboard bracket is a function button, so the antenna cannot be installed, so the antenna can only be installed on the other side. The other side is a large-capacity battery, which is the biggest killer affecting the performance of the antenna.

3. After close cooperation and analysis by structural engineers and RF engineers, isolation foam with a thickness of 5MM is added to the ANTENNA PCB board to create a reasonable safe distance between the antenna and the battery and minimize the impact of battery radiation on the antenna.

4. The determination of the antenna position and the space given by the structural engineer determine the antenna size, so we define the antenna size as 100* 17MM in length.

5. The use of engraving machine allows engineers to greatly shorten the development time, after 5 times of rigid sample making, finally successfully developed a long 100* wide 17* thick 1MM double panel antenna, up to 4.8dB gain and 44% efficiency, and double panel antenna grounding becomes larger, perfect improve the antenna anti-interference ability and long-distance transmission superior performance.

Economic benefits:

The customer successfully launched the product, which has sold 500,000 units and is still booming.